Supercharging thanks to immersive cooling systems - the search for suitable materials

As mobility increases, so do the demands on the speed of the charging process. In fact, there are now more and more fast-charging stations where electric cars can be refueled at breakneck speed: There, thanks to a power of several hundred kilowatts, a battery can sometimes be filled to about 80 percent within just 30 minutes! However, since an extremely high amount of energy flows during such a charging process - it exceeds the energy flowing in the opposite direction by a factor of two to three even during high-performance operation of an electric racing car - the battery heats up considerably.

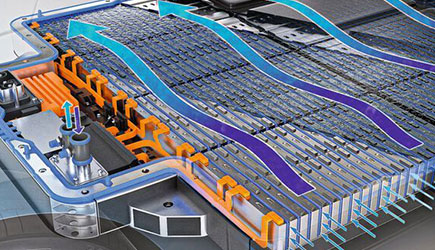

This intense heating poses the risk of permanent damage to the battery: It can lead to reduced power consumption and a shortened service life. Cooling systems are available to prevent this, although the current systems are no longer able to cope with the extreme demands of rapid charging processes. For this reason, research into alternative cooling systems has been going on for some time. In contrast to conventional systems, which cool the entire cell system from the outside, this new approach to liquid cooling is based on the principle of battery immersion cooling.

Immersion cooling systems effectively dissipate heat

In this form of cooling, the cells are surrounded by the cooling medium, which absorbs the heat generated and dissipates it directly. The challenge with this type of cooling system is to find suitable materials, because the cooling media must have different chemical properties than conventional ones due to their direct contact with the cells. One important requirement is that of electrical insulating properties.

The automotive industry is therefore testing various materials and substance classes that could be used for such immersive cooling systems. A central component of the systems are sealing elements, others are cell spacers, media storage and connecting elements: The chemical properties of all these components must be adapted to those of the respective cooling medium.

Study on the suitability of polymer materials

As part of a wide-ranging study carried out by Freudenberg Sealing Technologies, various polymer materials were investigated with regard to their compatibility with different cooling media. The fluids tested included ester-based oils and isoparaffinic oils - the former are commonly used in direct cooling. Fluids currently under development were also analyzed. The investigation is intended to provide a solid database for future inquiries from customers.

As Dr. Tobias Möller, materials developer, explains, the investigation was guided by two main questions: First, the effects of the liquid cooling media on the polymer sealing materials and the extent to which they swell were to be examined. Secondly, it was to be investigated whether and, if so, how the polymer materials affect the fluids in the opposite direction.

In the investigation, test specimens were taken from the polymer materials in standardized form and immersed in the cooling fluids for a specific period of time. In order to take long-term effects into account, the temperature was significantly increased compared with that normally used in battery systems. In a second step, the properties of the test specimens relevant to the functionality of seals were identified over their entire service life. These include weight, volume, elongation at break, hardness and recovery behavior.

Mutual effects

The sophisticated experimental set-up provided useful and, in some cases, unexpected findings. This applies in particular to the behavior of some recently developed fluids. As the head of materials pre-development at Freudenberg Sealing Technologies, Dr. Boris Traber, explains, the insights gained in the study into the behavior of polymer materials in fluid cooling media form the basis for the development of seals and spacer components that will later go into series production.

Conversely, more is now known about the behavior of fluids under the influence of polymer materials. As a result, Freudenberg Sealing Technologies can supply more and more customers in the automotive industry with the appropriate immersion cooling solutions for batteries and accumulators.

Sources: elektronikpraxis.de, 24.03.2023, Dipl-Ing.(FH), Hendrik Härter

Image: Freudenberg, Sealing Technologies